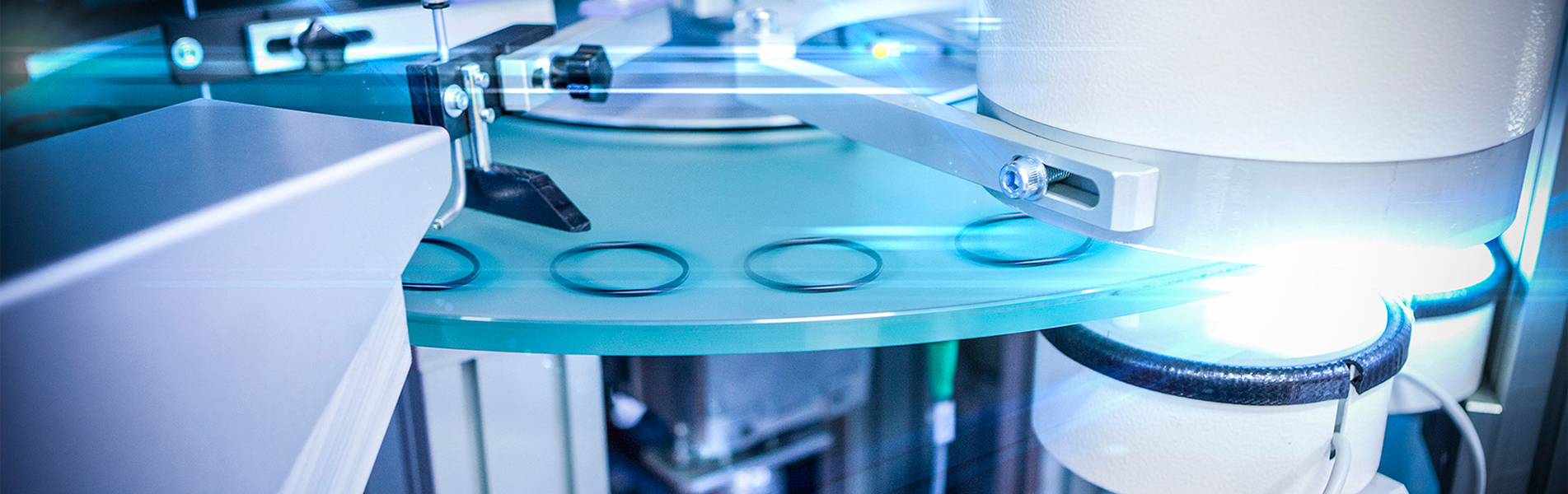

Youngpool Technology's Airblade series dry ultrasonic cleaning machines innovatively utilize the principles of aerodynamics to generate high-speed ultrasonic airflow at the outlet of the dust removal head. By using the ultrasonic vibration and high-speed flow of air, it enables dust particles to overcome the adhesion to the surface of the product. All dust and foreign particles are then sucked away through negative air pressure. This is a non-contact cleaning method that can perfectly handle various 3D surfaces, with no consumables

and zero damage to the product.

Widely use industries such as SMT electronics manufacturing, semiconductors, solar energy, LCD displays, lithium batteries, etc., it rapidly and efficiently removes dust particles from the surface of products to ensure the quality of subsequent processes thus improve product yield.

● No consumables.

● Intelligent plasma treat with triple actions, eliminate static charge.

● Perfectly handles various 3D surfaces such as steps, through-holes, etc.

● Utilizes clean air as a medium for non-contact cleaning, ensuring no damage to products and preventing secondary pollution.

● Closed-loop system that preserves airflow and pressure balance in the shop-floor, without contaminating the environment.

● Compact design, easy to install and maintain.

Technical specifications

|

Model |

A-500 |

A-510 |

A-520 |

|

Track height(mm) |

900±50 |

||

|

Track mode |

Standard single track Optional dual tracks, without shuttle |

Standard single track |

Standard dual tracks |

|

Cleaning product width(mm) |

Single track M:50-350 L:50-590 Dual tracks:80-300 |

80-590 |

80-300 |

|

Cleaning product length(mm) |

Unlimited |

≤510 |

≤510 |

|

Cleaning method |

Dry type ultrasonic airflow |

||

|

Air source pressure(kgf/cm²) |

5-8 |

||

|

Top side clearance(mm) |

Standard Max.15,Optional Max.50 |

||

|

Bottom side clearance(mm) |

Max. 23 |

||

|

Cleaning capacity |

Non-sticky dust removal rate of over 97% |

||

|

MES |

Optional |

||

|

Power supply |

220V 50Hz |

||

|

Power(kw) |

4 |

||

|

Noise(db) |

≤75 |

||

|

Weight(kg) |

365 |

900 |

950 |

|

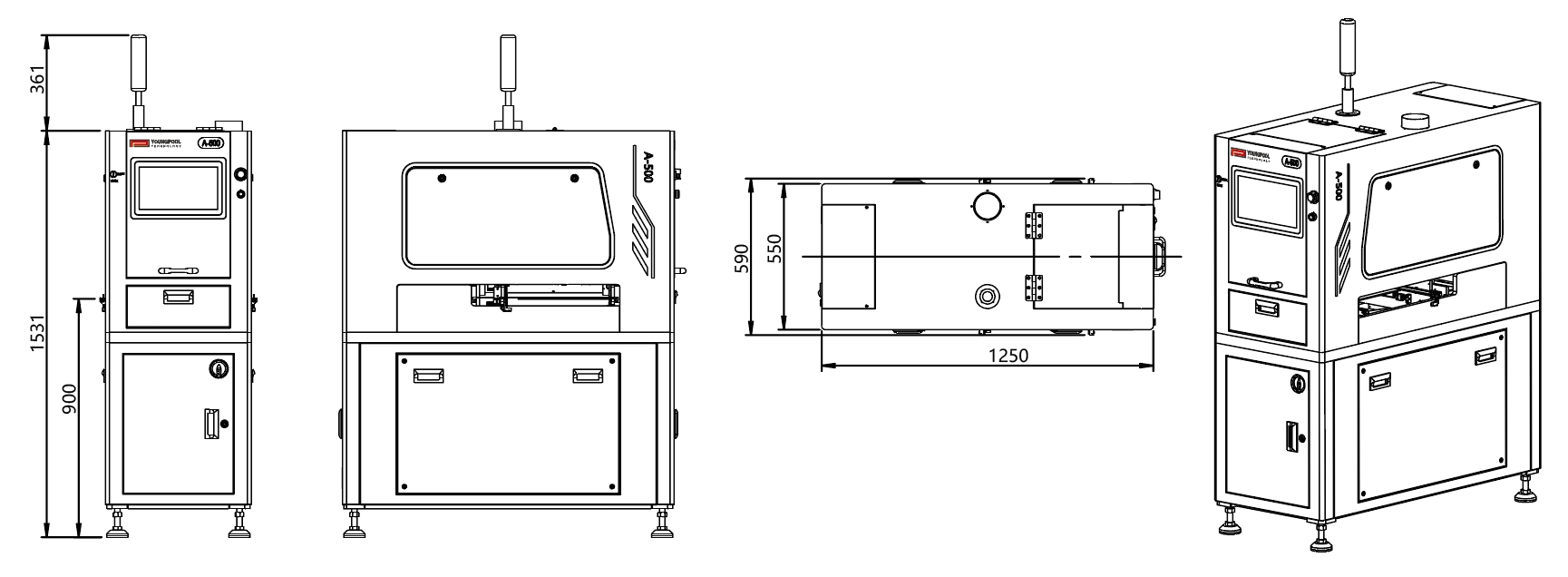

Reference dimension(mm) |

W550 x D1250 x H1530 |

W650 x D3400 x H1530 |

|

Dimensions

● Published in Jan. 2025 , All Rights Reserved

● All specifications are subject to change as a result of technical developments or advances. For questions on our products,

please contact Youngpool Technonlogy (shicx@youngpool.com) or our local representative(s)

IPv6 network supported

IPv6 network supported