Categories

New Blog

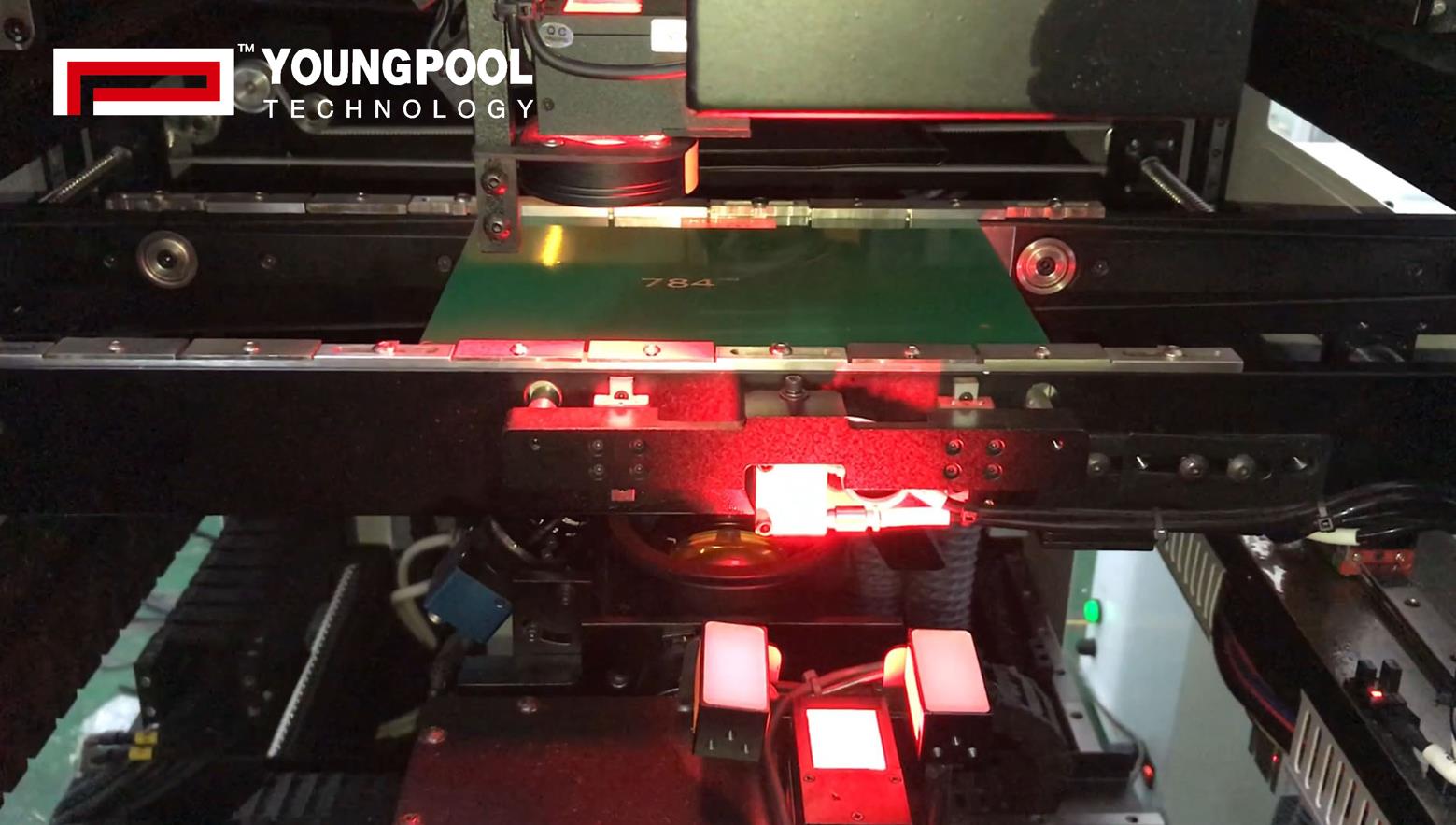

UV laser marking machine to PCB board metal parts manufacturing a level

Apr 19, 2022Laser marking machine is a permanent mark on the surface of the laser beam, the traditional metal products is handmade stickers (damage, contamination, unable to recognize) or code (to human body harm degree is very big, there are chemical composition, material long time investment, high cost), the traditional way of stickers, is easy to damage, contamination, etc to identify defects, while printing in addition to the above disadvantages, There is also a long time input of consumables, high cost and chemical substances in the ingredients, which do great harm to human body. Moreover, the way of stickers or inkjet code seriously limits the development of the fine degree of metal products industry.

Since the birth of UV laser marking machine, it takes PCB and the metal parts on the PCB board to a higher level. UV laser marking is another big innovation after laser application, is a new breakthrough in processing technology, new non-contact processing, no chemical pollution, no wear. Mark the process mode. In recent years, with the increasing application of laser technology, it is effectively combined with computer science and technology, so as to break through another milestone in the development of laser marking processing.

UV laser marking machine can not only achieve metal parts on the PCB board, but also in non-metallic products, resin, rubber, plastic and paper products on the radium LOGO LOGO, text patterns, two-dimensional code, code, safety code and serial number, UV laser marking machine has the advantages of fast marking, high efficiency, without marking consumables.

At present, UV laser marking metal machining technology and the traditional marking technology has tremendous breakthrough, can be used to mark all kinds of non-metal and metal materials, especially suitable for brittle material, high melting point, high hardness materials, such as high energy density of laser beam characteristics gathered very careful, make the influence of the processing object is very small, it is helpful to reduce the loss of raw material, Effective integration of modern automation and computer systems to achieve fast processing.

Nowadays, with the rapid development of laser marking machine, laser marking machine processing metal technology in the actual production is more combined with computer technology. Now its application has been paid attention to by various domestic enterprises, and its powerful function to replace the advantages of traditional marking methods.